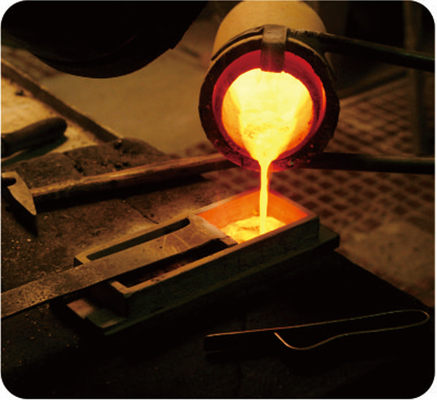

Induction melting equipment for steel / iron / copper / aluminum / precious metals melting

Major Features

1,Medium frequency induction heating machine adopts solid state IGBT frequency conversion control technologies ,it has all kinds of protection control ,giving signal under conditions of over current ,water shortage ,overheating ,over voltage ,short circuit ,and phase missing ,as a result ,the reliability is greatly enhanced.

2,It has the function display of current ,voltage , and timing ,making the working condition easily perceived ,and giving guidance to induction coil design ,capacitance control.

3,Small size ,light weight ,requires no more than 1sqm,and movable.

4,Continuously beating ability for 24 hours.

5,Low power consumption ,with electromagnetic grinding capability ,providing uniform smelting.

6,Better heating penetration and even temperature inside the melting metal.

7,According equipment power and melting weight ,generally melting time 30~50Minutes/furnace .When furnace full cooling ,heating time 50~60Minutes.When furnace hot ,heating time 20~30Minutes.

Compare with other equipment melting

1, VS resistance heated furnace

a, High heat efficiency ,melting fast.

b,Small size ,save energy 30%.

c, Resistance or silicon carbide stock easy to damage .

2, VS Coal ,Gas ,diesel furnace

a, Facilitate the adjustment solution composition and temperature ,the bubble of foundry less 1/3 to 1/4 ,reject rate down 1/2 to 2/3 ,so that cast have a higher mechanical strength;)

b, Reduced the oxidation of burning;

c, Induction melting can melt scrap of processing and the small pieces because of its electromagnetic stirring effect .reducing the cost of materials .Reduce environmental pollution ;noise is far below the towering equipment .Labor intensity of workers and working conditions have been improved;

d,Cast-iron crucible used in Coal and gas furnace is harmful to the aluminum alloy by increasing impurity. Graphite crucible used in induction melting without such disadvantages.)

3, VS SCR or Frequency Melting Furnace

a,High heat efficiency ,melting fast.

b,Small size ,save energy above 20%.

c,Electromagnetic stirring effect is slight so service life of crucible is extended.

d,By adjusting the frequency to achieve power regulation ,so melting speed fast ,material elements of burning loss less and better energy saving ,in particular the heating of stainless steel ,copper ,silicon ,aluminum and other non-magnetic material ,thus reducing the cost of the casting.

Special note

1,Max .melting rate :calculated from second crucible

2,Size of crucible marked as holding weight of copper

3,Electricity consumption is affected by material quality ,operation of operator and grid voltage.

4,Such as equipment 70KW melting aluminum ,cost of melting 1T.

a,70% of resistance melting furnace

b,70% of frequency melting furnace

c,60% of diesel melting furnace

d,80% of SCR melting furnace

Technical parameter

| Type |

Steel or lron |

Copper or Precious Metals |

| 15KW Melting Furnace |

- |

5-10kg |

| 25KW Melting Furnace |

4-8kg |

10-20kg |

| 40KW Melting Furnace |

10-14kg |

20-30kg |

| 60KW Melting Furnace |

18-22kg |

40-50kg |

| 70KW Melting Furnace |

25kg |

60-80kg |

| 80KW Melting Furnace |

40kg |

80-100kg |

| 100KW Melting Furnace |

50kg |

100-150kg |

| 160KW Melting Furnace |

100kg |

150-200kg |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!