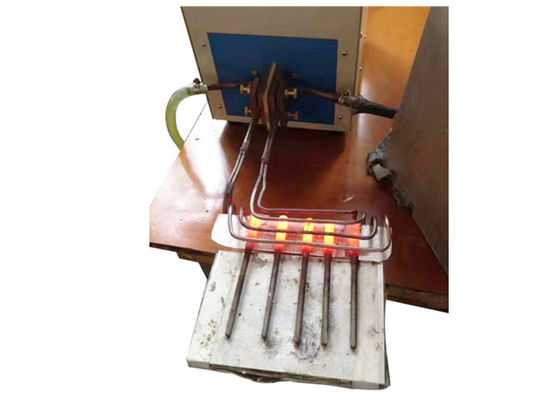

60KW High Frequency Portable Steel Bolt Heating Induction Machine

| Model |

GY-60AB (Three phase) |

| work power |

340V-430V |

| input current |

60A |

| Fluctuating output power |

60KW |

| fluctuating frequency |

30-80KHZ |

| output current |

400-2400A |

| the flow rate of cooling water |

0.08-0.16Mpa 7.6L/Min |

| water temperature protection point |

40C |

| product size |

main : 640x280x550 mm |

| transformer : 510x260x410 mm |

| net weight |

main : 37.5 kgs |

| transformer : 32.5 kgs |

Delivery Time: within 3 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

Bolt Heating Induction Machine Feature

Induction heating allows the targeted heating of an applicable item for applications including surface hardening, melting, brazing and soldering and heating to fit. Iron and its alloys respond best to induction heating, due to their ferromagnetic nature. Eddy currents can, however, be generated in any conductor, and magnetic hysteresis can occur in any magnetic material. Induction heating has been used to heat liquid conductors (such as molten metals) and also gaseous conductors. Induction heating is often used to heat graphite crucibles (containing other materials) and is used extensively in the semiconductor industry for the heating of silicon and other semiconductors. Utility frequency (50/60 Hz) induction heating is used for many lower-cost industrial applications as inverters are not required.

Scope of induction heating application

1. Adopt MOSFET. High frequency, energy saving and steady.

2. Heating speed is fast and high efficiency.

3. Only heat the part inside the coil, little distortion.

4. Short heating time. There is no oxide layer on the surface of the workpiece.

5. Easy operation, good working environment and no pollution.

6. Control heating temperature and heating time easily. Ensure heating quality and could achieve line production.

Our services

1).Pre-sale service:

1.Inquiry and consulting service

2.recommend the most suitable for our customers according to their requirements

3.Sample testing support

4.working videos available

5.View our factory

In-sale service:

1. Strictly manufacture the machine, according to relevant technical standards.

2. Take run test, according to relevant equipment test run regulations.

3. Strictly check up the machine, before delivery

4. Delivery on time.

Induction forging applications

(1) Round steel categories:

A. bolts, nuts, drill head hot forge, the car U-bolts, anchor bolt, connecting rod, non-standard parts processing, conductive rod

B. stainless steel tableware, stainless steel bolts and nuts

C. tools: pliers, bolt cutters, pipe clamp, water pump pliers, pliers, wrenches, ratchet wrenches, masonry chisel,

D. Other: sewing gadgets, jack head, boss chair, shackles, hand rings, flowers Lancashire body, feet kidnapper, tricycle axle, briquettes machine Chong-pin, roll gate axis, articulated manifolds, hot-rolled twist drill, Hot-rolled rebar, hot-rolled woodworking drill, bearing

(2) sheet/plate categories:

A. forged stainless steel cutlery, automotive steel plate.

B. sheet folding: folding iron hand jack,

metal folding channel, automotive steel, hot rolled construction steel buckle, automotive leaf spring

C. embossed: Iron Works

embossing, embossing motorcycle brake pedal heating, sanitary ware.

D. Forming: bending, upsetting head, punching, flatten, step

by step tight angle iron molding, from nails, rasp, sanitary ware

(3) pipe deformation: pipe heat distortion, fire extinguishers

stretching, stretching cylinders, fans rose shaped brackets bend, pipe up hole, bicycle fork shrinkage, food machinery punching

(4) other categories: Electric Vehicle wrist, drill rod, drill bits, copper pieces (communication, air conditioning parts), trains

pin, watch cases, railway rail pressure ring.

CALENTAMIENTO P/INDUCCION,HORNO DE INDUCCION,MAQUINA DE CALENTAMIENTO

LOS DEMAS APARATOS PARA TRATAMIENTO TERMICO DE MATERIAS POR INDUCCION O PERDIDAS DIELECTRICAS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!